Research and Experience

The Gummix series is the result of decades of experience and pioneering research. In this way the Gummix series continues to be further perfected and fulfils all expectations with every new generation

From hand soldering through to Laser applications

Gummix series soldering wires can be used for a particularly wide range of uses. Due to the almost entirely splash-free behaviour the soldering wires are especially well suited to contactless soldering applications, such as laser, induction wave soldering and xenon lamp soldering, but also especially for robotic soldering and for entirely traditional hand soldering.

A further plus for the Gummix ist he excellent suitability for flexible braiding, structural components and relays.

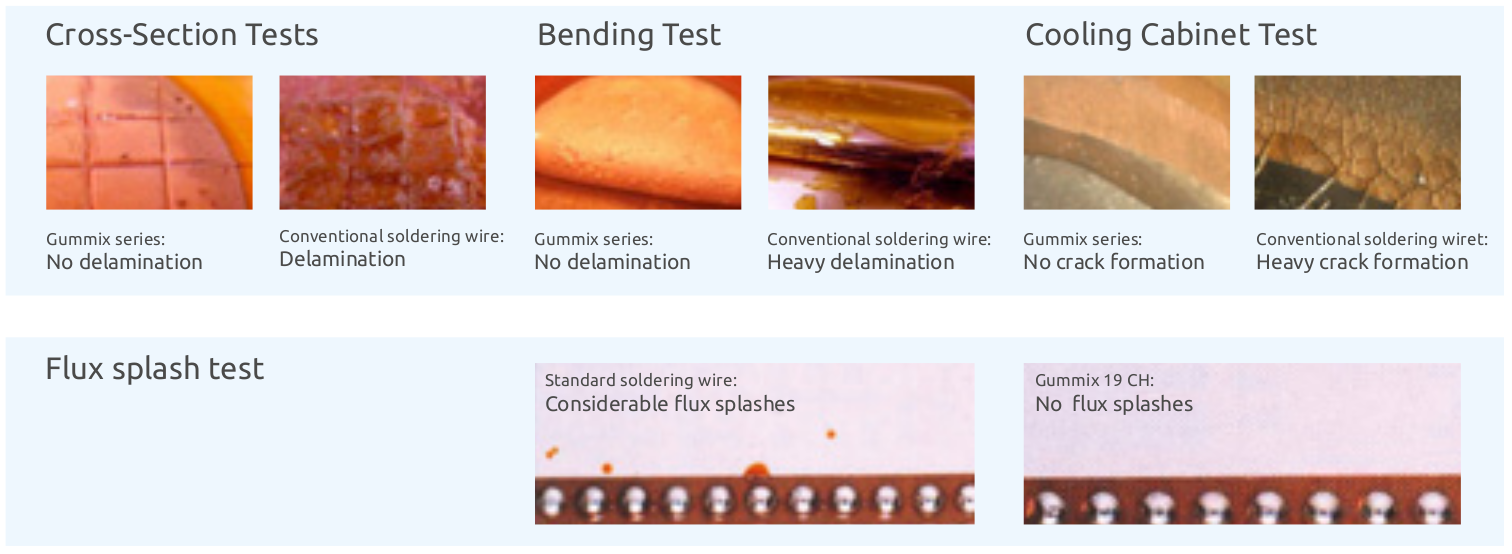

Test winner: the Gummix series

We compared the performance of the Gummix series with the performance of a conventional soldering wire in a number of tests.

The result:

The Gummix series was the winner in every test.

Cross-section test

Cross-section test

Cooling cabinet test

Cooling cabinet test

Bending test

Bending test

Flux splash test

Flux splash test

Convince yourself of this.

Gummix 21 Zeta – the latest generation of the best-selling series

Lengthy research and development work have paid off: With the new Gummix 21 Zeta we have further perfected the qualities of the Gummix series. No delamination, no crack formation and as good as no flux splashes.

Flux splash test for hand soldering

Top of the Gummix series: Gummix 21 Zeta shows fewer splashes than every other Gummix soldering wire.

| °C |

GUMMIX-21 Zeta |

GUMMIX-SB RMA |

GUMMIX-19 CH |

GUMMIX-19 NH |

| 320°C |

2 |

2 |

5 |

6 |

| 350°C |

2 |

2 |

7 |

10 |

| 380°C |

3 |

4 |

8 |

22 |

- Test conditions

- Temp.: 320°C, 350°C, 380°C

- Feeding volume: 2mm / shot

- Feeding speed: 10mm / sec

- Total 3 shots (2mm x 3 = 6mm)

- Test method

- with automatic solder feed

- Count splashes using a

thermo-paper

Why you can manufacture more economically with the Gummix series

The reason for this is very simple: The Gummix flux creates as good as no flux splashes at high temperatures. This means that you have almost no finishing work and maintenance work in production.

And that really saves you money.

Error rate lowered from 400ppm to 4ppm

"Grade A Plus!" is the clear verdict of one customer from the automotive industry. After converting from a conventional soldering wire to the Gummix series, production became much more effective and economical, as the error rate now lies at only 4 ppm (parts per million).

The reason for the low error quota is the Gummix flux or the core flux, which always guarantees an optimum soldering result without trapping any air.