Flux Types

In accordance with IPC-J-STD-004

Flux Types in accordance with IPC-J-STD-004

IPC

IPC is a global trade association dedicated to the competitive excellence and fi nancial success of its member companies which represent all facets of the electronics interconnect industry, including design, printed circuit board manufacturing and electronics assembly.

As a member-driven organization and leading source for industry standards, training, market research and public policy advocacy, IPC supports programs to meet the needs of an estimated $1.5 trillion global electronics industry.

Founded in 1957 as the Institute of Printed Circuits with 6 Member Companies

Founded in 1957 as the Institute of Printed Circuits with 6 Member Companies

Strong Foundation as Technical Organization Dedicated to Meeting Industry Needs

Strong Foundation as Technical Organization Dedicated to Meeting Industry Needs

Focus on Design, PCB Manufacturing and Electronics Assembly.

Focus on Design, PCB Manufacturing and Electronics Assembly.

Benefi ts of IPC Standards

The benefi ts of IPC Standards is that they are used and recognized worldwide, and the most important standards are available in almost all the languages. The IPC Standards cover the complete process from the Design, Bare Board Manufacturing, Assembly and Box Building including Fiber Optics.

In the following Spec Tree you can see an overview of the most used IPC Standards:

IPC Classification

Accept and/or reject decisions shall be based on applicable documentation such as contracts, drawings, specifications, standards and reference documents.

IPC defines three product classes, which are as follows:

class 1 - General Electronic Products Includes products suitable for applications where the major requirement is function of the completed assembly.

Class 2 - Dedicated Service Electronic Products Includes products where continued performance and extended life is required, and for which uninterrupted service is desired but not critical. Typically the end-use environment would not cause failures.

Class 3 - High Performance/Harsh Environment Electronic Products Includes products where continued high performance or performance-on-demand is critical, equipment downtime cannot be tolerated, end-use environment may be uncommonly harsh, and the equipment must function when required, such as life support or other critical systems.

The customer (user) has the ultimate responsibility for identifying the class to which the assembly is evaluated. If the user and manufacturer do not establish and document the acceptance class, the manu- facturer may do so.

IPC J-STD-004B Requirements for Soldering Fluxes

IPC J-STD-004B December 2008 and J-STD-004B-Amendment-1 November 2011

According to the J-STD-001 Requirements for Soldered Electrical and Electronic Assemblies it is mandatory that the flux should fulfil the requirements of the J-STD-004.

The J-STD-004 is a Flux classification document, all fluxes can be subdivided into 1 to 24 Flux Classifications.

The fluxes shall be classified according to the materials of composition and flux type, the flux designators identify both composition and type of fluxes.

24 Flux Certificates

| Flux Materials |

Flux Activity |

Flux Designator |

| Rosin (RO) |

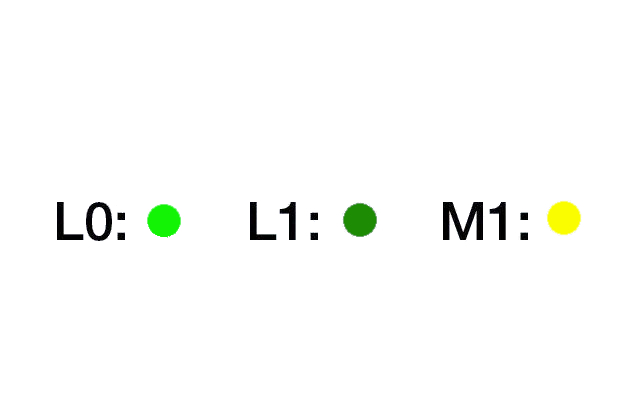

Low (0%) L0 |

ROL0 |

| Low (<0,5%) L1 |

ROL1 |

| Moderate (0%) M0 |

ROM0 |

| Moderate (0,5%-2,0%) M1 |

ROM1 |

| High (0%) H0 |

ROH0 |

| High (<2,0%) H1 |

ROH1 |

| Resin (RE) |

Low (0%) L0 |

REL0 |

| Low (<0,5%) L1 |

REL1 |

| Moderate (0%) |

REM0 |

| Moderate (0,5%-2,0%) M1 |

REM1 |

| High (0%) H0 |

REH0 |

| High (<2,0%) H1 |

REH1 |

| Organic (OR) |

Low (0%) L0 |

ORL0 |

| Low (<0,5%) L1 |

ORL1 |

| Moderate (0%) |

ORM0 |

| Moderate (0,5%-2,0%) M1 |

ORM1 |

| High (0%) H0 |

ORH0 |

| High (<2,0%) H1 |

ORH1 |

| Inorganic (IN) |

Low (0%) L0 |

INL0 |

| Low (<0,5%) L1 |

INL1 |

| Moderate (0%) |

INM0 |

| Moderate (0,5%-2,0%) M1 |

INM1 |

| High (0%) H0 |

INH0 |

| High (<2,0%) H1 |

INH1 |

Rosin- based Flux (RO – Type):

Rosin (Colophony) is general extracted from pineapple tree juice.

Rosin (Colophony) is general extracted from pineapple tree juice.

Solid at room temperature

Solid at room temperature

Chemically inactive at room temperature

Chemically inactive at room temperature

Isolating at room temperature

Isolating at room temperature

Rosin melts at approx. 72°C

Rosin melts at approx. 72°C

Organic acids become active at approx. 108°C

Organic acids become active at approx. 108°C

His optimum function is at approx. 262°C

His optimum function is at approx. 262°C

At temperatures above 346 oC this flux becomes inactive and polymerises, which causes problems with cleaning the residue

At temperatures above 346 oC this flux becomes inactive and polymerises, which causes problems with cleaning the residue

| Rosin (RO) |

Natural Rosin (Colophony) Natural Rosin (Colophony) |

The IPC-J-STD-004 The IPC-J-STD-004

standard designates this flux as – RO

|

Resin- based Flux (RE – Type):

Resin is a common used technical term with a double meaning.

Resin is a common used technical term with a double meaning.

It encloses a variety of natural and synthetically resinous products.

It encloses a variety of natural and synthetically resinous products.

| Rosin (RE) |

The IPC-J-STD-004 The IPC-J-STD-004

standard designates this flux as - RE

|

Water soluble (Organic Acid) Flux:

Original build up by organic acids different from Rosin or Resin.

Original build up by organic acids different from Rosin or Resin.

Organic Flux (OR) often called OA Flux

Organic Flux (OR) often called OA Flux

Common on market as WSF’s (Water Soluble Flux)

Common on market as WSF’s (Water Soluble Flux)

Many 'low solids fluxes' fall into the OR category

Many 'low solids fluxes' fall into the OR category

As the name already tells us, this flux is build up with water soluble chemicals.

As the name already tells us, this flux is build up with water soluble chemicals.

After the soldering operation the flux residue can be easily cleaned with tap water.

After the soldering operation the flux residue can be easily cleaned with tap water.

This flux is very popular, because it is free of anti-pollution tax, as paid by other flux types.

This flux is very popular, because it is free of anti-pollution tax, as paid by other flux types.

| Rosin (RE) |

The IPC-J-STD-004 The IPC-J-STD-004

standard designates this flux as – RE

|

Inorganic (IN) Flux:

Flux with inorganic salts are commonly not used for soldering PCBs because the extreme corrosive residue, but are sometimes used for soldering non-electric products. (i.e. lightning rod materials)

| Inorganic (IN) |

The IPC-J-STD-004 The IPC-J-STD-004

standard designates this flux as – IN

|

J-STD-004 Flux Classification

This means: the degree of effectiveness of the Flux.

The worse the solder ability of the PCB surface is, the higher the flux activity should be to create a good wetting.

Not activated or activated (L = low, M = moderate, H = high)

If you hear this you should logically always choose the most active flux to create a good wetting in all situations. Unfortunately it is not so easy! If you use high activated flux, you have more problems with oxidation of the flux residue.

The IPC-J-STD-004 Classifications

| Flux synthesis |

ROsin ROsin |

REsin REsin |

ORganic ORganic |

INorganic INorganic |

|

|

| Flux activity |

Low Low |

Moderate Moderate |

High High |

|

|

Halogen or

Halide free

|

L0 L0 |

L1 L1 |

|

Flux types (activity/Residue)

Table 3.1 Test Requirements for Flux Type Classification

| Flux Type |

Qualitative Copper Mirror2 |

Qualitative Halide(Optional) |

Quantitative Halide |

Qualitative Corrosion Test |

Conditions for Passing 100 MQ SIR Requirements2 |

Conditions for Passing ECM Requirements2 |

| Silver Chromate(Cl, Br) |

Spot Test(F) |

((Cl, Br, F)(by weight) |

| L0 |

No evidence of mirror breakthrough |

Pass3 |

Pass3 |

0.0% 1 |

No evidence of corrosion |

Uncleaned6,7 |

Uncleaned6,7 |

| L1 |

Pass3 |

Pass3 |

<0.5% |

| M0 |

Breakthrough in less than 50% of test area |

Pass3 |

Pass3 |

0.0% 1 |

Minor corrosion acceptable |

Cleaned7 or Uncleaned8 |

Cleaned7 or Uncleaned8 |

| M1 |

Fail4 |

Fail4 |

0.5% to 2.0% |

| H0 |

Breakthrough in less than 50% of test area |

Pass3 |

Pass3 |

0.0% 1 |

Major corrosion acceptable |

Cleaned |

Cleaned |

| H1 |

Fail4 |

Fail4 |

>2.0% |

Flux activity L: Copper Mirror Test

50 nm thick layer of Copper on a glass plate.

50 nm thick layer of Copper on a glass plate.

Put one drop of flux on the mirror.

Put one drop of flux on the mirror.

Inspect the effect of the Copper layer after 24 hours

Inspect the effect of the Copper layer after 24 hours

The flux shall be classified as type L only if there is no complete removal of the copper film.

The flux shall be classified as type L only if there is no complete removal of the copper film.

If there is any removal of the copper film, as evidenced by the background showing through the glass, then the flux shall not be classified as type L.

Flux activity M: Copper Mirror Test

50 nm thick layer of Copper on a glass plate.

50 nm thick layer of Copper on a glass plate.

Put one drop of flux on the mirror.

Put one drop of flux on the mirror.

Inspect the effect of the Copper layer after 24 hours.

Inspect the effect of the Copper layer after 24 hours.

If there is complete removal of the copper only around the perimeter of the drop (less than 50% breakthrough), then the flux shall be classified as type M.

Flux activity H: Copper Mirror Test

50 nm thick layer of Copper on a glass plate.

50 nm thick layer of Copper on a glass plate.

Put one drop of flux on the mirror.

Put one drop of flux on the mirror.

Inspect the effect of the Copper layer after 24 hours.

Inspect the effect of the Copper layer after 24 hours.

If the copper film is completely removed (greater than 50% breakthrough), then the flux shall be classified as type H.

24 Flux Certificates

| Flux Materials |

Flux Activity |

Flux Designator |

| Rosin (RO) |

Low (0%) L0 |

ROL0 |

| Low (<0,5%) L1 |

ROL1 |

| Moderate (0%) M0 |

ROM0 |

| Moderate (0,5%-2,0%) M1 |

ROM1 |

| High (0%) H0 |

ROH0 |

| High (<2,0%) H1 |

ROH1 |

| Resin (RE) |

Low (0%) L0 |

REL0 |

| Low (<0,5%) L1 |

REL1 |

| Moderate (0%) |

REM0 |

| Moderate (0,5%-2,0%) M1 |

REM1 |

| High (0%) H0 |

REH0 |

| High (<2,0%) H1 |

REH1 |

| Organic (OR) |

Low (0%) L0 |

ORL0 |

| Low (<0,5%) L1 |

ORL1 |

| Moderate (0%) |

ORM0 |

| Moderate (0,5%-2,0%) M1 |

ORM1 |

| High (0%) H0 |

ORH0 |

| High (<2,0%) H1 |

ORH1 |

| Inorganic (IN) |

Low (0%) L0 |

INL0 |

| Low (<0,5%) L1 |

INL1 |

| Moderate (0%) |

INM0 |

| Moderate (0,5%-2,0%) M1 |

INM1 |

| High (0%) H0 |

INH0 |

| High (<2,0%) H1 |

INH1 |

Flux types (activity):

L0-type flux: all type R, some RMA, some Low Solids ,,No Clean“.

L0-type flux: all type R, some RMA, some Low Solids ,,No Clean“.

L1-type flux: most RMA, some RA

L1-type flux: most RMA, some RA

M0-type flux: some RA, some Low Solid „No clean“

M0-type flux: some RA, some Low Solid „No clean“

M1-type flux: most RA, some RSA

M1-type flux: most RA, some RSA

H0-type flux: some water soluble

H0-type flux: some water soluble

H1-type flux: some RSA, most water soluble and synthetic activated

H1-type flux: some RSA, most water soluble and synthetic activated

|

| Flux Activity |

Flux Types |

| L0 |

All R |

| Same RMA |

| Same Low soids, No-Clean |

| L1 |

Most RMA |

| Same RA |

| M0 |

Same RA |

| Same Low solids, No-Clean |

| M1 |

Most RA |

| Same RSA |

| H0 |

Same water soluble |

| H1 |

Same RSA |

| Most water soluble |

| Most synthetic activated |

|

|

| Activators |

|

Speed up |

| |

| Vehicles |

|

Carriers |

| |

| Solvent |

|

Solve |

| |

| Special Additives |

|

Special properties |

Activators

Activators are chemicals which are added in small portions on to the flux to remove oxides which are located on the base material.

When an activator functions, it is a corrosive action:

Low activated flux = corrosive at room temperature

High activated flux = corrosive at solder temperature

Flux activity systems are build up with:

Acids,

Acids,

Halides,

Halides,

or a combination of both.

or a combination of both.

Flux Activators can be:

Halogens,

Halogens,

Organic/Inorganic acids

Organic/Inorganic acids

Synthetic activators

Synthetic activators

The most characteristically chemical property of halogens is the possibility to oxidize.

Fluor has the property to oxidize.

Almost all elements of group 7 of the periodic system of elements (Fluorine, Chlorine, Bromine and Iodine) react directly with metal, with decrease reactivity below in the group.

The reaction should be activated by heat or UV-light.

Halogenides are halogen oxides.

Halogens are group VII in the periodic system of elements:

Fluorine (F)

Fluorine (F)

Chlorine (Cl)

Chlorine (Cl)

Bromine (Br)

Bromine (Br)

Iodine (I)

Iodine (I)

Astatine (At) (Radioactive and unstable)

Astatine (At) (Radioactive and unstable)

Halogen:

The presence of halogen in flux is indicated with:

0 No halogen (oxides) in Flux (residue).

0 No halogen (oxides) in Flux (residue).

1 Halogen (oxides) in Flux (residue).

1 Halogen (oxides) in Flux (residue).

Minimum percentage halogen part per weight of solid constituents in the flux:

L0, M0, H0 = 0,0%

L0, M0, H0 = 0,0%

Halogen free activators:

Chlorine compositions: Ammonium Chlorines & Hydro Chlorines

Chlorine compositions: Ammonium Chlorines & Hydro Chlorines

Acids: Phosphor Acids & Carboxyl Acids

Acids: Phosphor Acids & Carboxyl Acids

Salts

Salts

Maximum percentage halogens part per weight of solid constituents in the flux:

L1, <0,5%

L1, <0,5%

M1, 0,5% to 2,0%

M1, 0,5% to 2,0%

H1, > 2,0%

H1, > 2,0%

The carrier is build up with:

a solid substance or

a solid substance or

a non-volatile liquid or

a non-volatile liquid or

a combination of both.

a combination of both.

Three functions of a carrier:

1. A carrier is used as a dissolver of materials which are formed during the reaction between oxides and activators on high temperatures.

2. It takes care, that no air inclusion can occur in the solder connection or on the soldering surface. It functions as a blanket.

3. It takes care for a good heat transfer between the solder and the surface.

Solvents:

The solvent in the liquid flux (i.e. in a wave soldering machine), has a primary function to drive off the activators and the vehicles to the surface of the PCB.

During the preheat stage the solvent will evaporate. During soldering only the activators and the carriers will remain.

Special additives

These additives are added to the flux with deviations and for special functions:

Stabilizers – for thermal stability

Stabilizers – for thermal stability

Inhibitors – to minimize oxidation

Inhibitors – to minimize oxidation

Dyes – colourize the flux

Dyes – colourize the flux

Flux types (activity/Residue):

Required SIR Test. The SIR requirements for fluxes shall be determined in accordance with IPC-TM- 650, Test Method 2.6.3.3.

All SIR measurements on all test patterns shall exceed the 100 MΏ requirements when measured at 96 and 168 hours.

Both the initial insulation resistance (IR Initial, measurement taken after the 96 hour stabilization period) and the final insulation resistance.

(IR Final, measurement taken after exposure to bias for 500 hours) values shall be reported according to the test method.

| Flux Type |

Qualitative Copper Mirror2 |

Qualitative Halide (Optional) |

Quantitative Halide |

Qualitative Corrosion Test |

Conditions for Passing 100 MQ SIR Requirements2 |

Conditions for Passing ECM Requirements2 |

| Silver Chromate(Cl, Br) |

Spot Test(F) |

(Cl, Br, F) (by weight) |

| L0 |

No evidence of mirror breakthrough |

Pass3 |

Pass3 |

0.0% 1 |

No evidence of corrosion |

Uncleaned6,7 |

Uncleaned6,7 |

| L1 |

Pass3 |

Pass3 |

<0.5% |

| M0 |

Breakthrough in less than 50% of test area |

Pass3 |

Pass3 |

0.0% 1 |

Minor corrosion acceptable |

Cleaned7 or Uncleaned8 |

Cleaned7 or Uncleaned8 |

| M1 |

Fail4 |

Fail4 |

0.5% bis 2.0% |

| H0 |

Breakthrough in less than 50% of test area |

Pass3 |

Pass3 |

0.0% 1 |

Major corrosion acceptable |

Cleaned |

Cleaned |

| H1 |

Fail4 |

Fail4 |

>2.0% |

The criteria for passing the ECM test (Electro Chemical Migration Test) are:

1. IR Final3 (IR Initial)/10, that is the average insulation resistance shall not degrade by more than one decade as a result of the applied bias.

2. No evidence of electrochemical migration (dendritic filament growth) that reduces the conductor spacing by more than 20%.

3. No corrosion of the conductors; minor discoloration of one polarity of the comb pattern conductors is acceptable.

| Flux Type |

Qualitative Copper Mirror2 |

Qualitative Halide (Optional) |

Quantitative Halide |

Qualitative Corrosion Test |

Conditions for Passing 100 MQ SIR Requirements2 |

Conditions for Passing ECM Requirements2 |

| Silver Chromate (Cl, Br) |

Spot Test(F) |

(Cl, Br, F) (by weight) |

| L0 |

No evidence of mirror breakthrough |

Pass3 |

Pass3 |

0.0% 1 |

No evidence of corrosion |

Uncleaned6,7 |

Uncleaned6,7 |

| L1 |

Pass3 |

Pass3 |

<0.5% |

| M0 |

Breakthrough in less than 50% of test area |

Pass3 |

Pass3 |

0.0% 1 |

Minor corrosion acceptable |

Cleaned7 or Uncleaned8 |

Cleaned7 or Uncleaned8 |

| M1 |

Fail4 |

Fail4 |

0.5% bis 2.0% |

| H0 |

Breakthrough in less than 50% of test area |

Pass3 |

Pass3 |

0.0% 1 |

Major corrosion acceptable |

Cleaned |

Cleaned |

| H1 |

Fail4 |

Fail4 |

>2.0% |

Labelling

The manufacturer must label each container of solder flux (J-STD-004) with following information:

The manufacturer’s name and address.

The manufacturer’s name and address.

Part number.

Part number.

Complies with J-STD-004.

Complies with J-STD-004.

Designation of the flux.

Designation of the flux.

The batch number.

The batch number.

The net mass of the flux.

The net mass of the flux.

The date of manufacturing and shelf life.

The date of manufacturing and shelf life.

Health, safety and environmental markings.

Health, safety and environmental markings.

Source: J-STD-004 & PIEK’s Flux Presentation

Rob Walls MIT/CID+

Managing Director

PIEK International Education Centre BV, Netherlands